Alumina ceramic (Al2O3) is an advanced ceramic material with many unique and beneficial characteristics. It is hard-wearing, injection molded, die pressed, cold isostatic pressed, slip cast and machined using advanced green body and biscuit machining techniques.

Alumina provides excellent corrosion resistance and high hardness, in addition to acting as an electrical insulator and withstanding thermal shock.

High Temperature Resistance

Modern alumina ceramics are among the hardest, strongest materials available, boasting excellent thermal, mechanical, chemical and electrical properties at room and elevated temperatures. Furthermore, they are highly resistant to corrosion from acids and alkalis that form solutions in their environment.

Metal coated Alumina sheets are highly hermetic, ideal for high vacuum systems, laser components, X-ray equipment and other applications requiring stability at high temperatures. Alumina also serves as an electrical insulator; no electrical current passes through it and it is nonreactive against chemicals.

High Resistance to Corrosion

Alumina ceramics exhibit excellent corrosion resistance against various media. Mechanical stress resistance depends on particle size and impurity distribution as well as an ability to form protective oxide coatings at grain boundaries.

High-purity alumina is one of the most sought-after ceramic materials for use in high-tech fields like semiconductor, vacuum deposition and CVD applications. Furthermore, it’s often employed in building and sanitary ceramics, industrial furnace tubes and thermal couple protectors – ideal applications.

Alumina can be easily pressed, extruded, tape cast and injection molded. To tailor its desirable properties further, its green body composition may be adjusted by adding elements such as chromium oxide for hardening purposes; silicon dioxide to increase temperature resistance; and zirconium oxide to decrease coefficient of thermal expansion.

High Thermal Conductivity

Alumina ceramics boast extremely high thermal conductivity and possess an extremely low coefficient of thermal expansion; additionally they’re extremely hard.

These qualities make alumina ceramics a suitable material for components that need to operate over a broad temperature range, as they offer electrical insulation properties as well as outstanding chemical stability.

They can be utilized for applications including alumina-to-metal feed throughs, X-ray component feed throughs and hermetic bushings, body armor for military applications as well as stopping small arms fire and medium caliber cannon shells.

High Dielectric Properties

Ceramics exhibit an exceptionally low dielectric loss when exposed to electromagnetic radiation, and are highly inert, not reacting with chemical reagents or reactants.

Alumina ceramics are ideal for applications requiring high resistance to corrosion and wear, such as pump components, media transfer systems for corrosive media transfer systems, medical laser equipment, X-ray tubes and electron microscopes.

International Syalons offers a complete lineup of advanced alumina products under its Aluminon brand name. These materials can be injection molded, die pressed, isostatically pressed or slip cast for use in various industries.

High Density

Alumina ceramics boast an extremely dense structure, meaning that there is a large amount of mass in its volume. This makes alumina ceramics highly resilient against shocks and makes them the go-to material when shock resistance is important.

Electrical insulation properties of silicon also excel, particularly at higher purity levels, while their resistance to acids and alkalis makes them suitable for use in environments prone to corrosion.

These characteristics make alumina ceramics an excellent choice for producing metalised products like spark plugs, transducer components and high vacuum equipment. Alumina ceramics also serve as excellent abrasive grains during metalizing and polishing processes.

High Wear Resistance

Alumina ceramics offer superior wear resistance over metal components, extending their service life significantly while decreasing maintenance costs, downtime and safety risks.

Modifying the composition of alumina ceramic bodies to improve specific desirable properties is possible. For instance, adding chromium oxide or manganese oxide increases hardness; silicon dioxide enhances thermal shock resistance and lifetime; zirconium oxide increases strength and wear resistance.

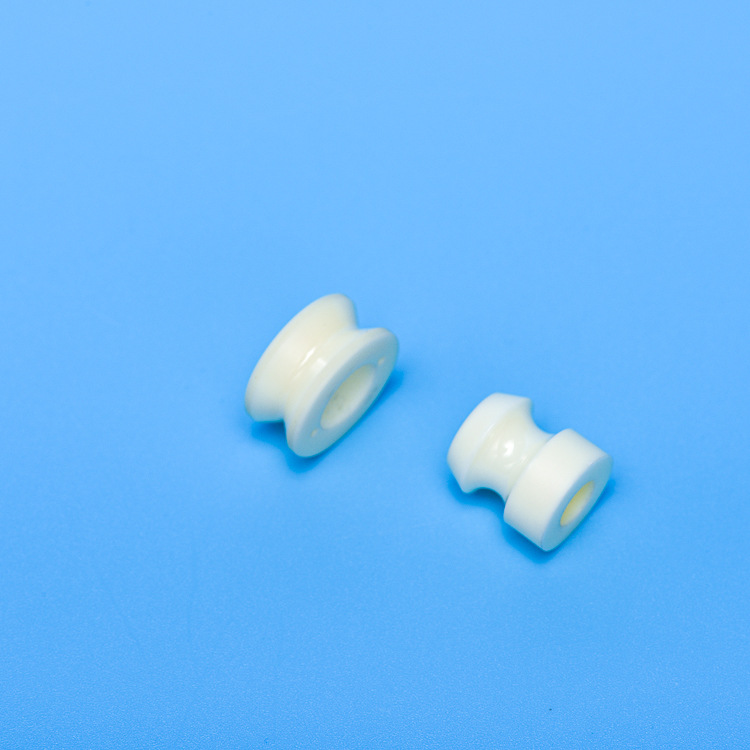

Alumina ceramic injection molding is the premier manufacturing method for complex alumina components, offering greater design freedom than dry pressing and being far simpler to work with.

High Impact Resistance

Alumina ceramic liners provide superior anti-wear protection for mining, mineral processing and metallurgy equipment such as coal conveying pipelines, heavy medium cyclones, grading systems and any easily worn system components such as silos, chutes or pumps.

Alumina boasts high strength, impact resistance and electrical insulation properties that make it an excellent material choice for spark plugs, ceramic to metal connections and circuit shells.

Alumina can be injection molded, die pressed, isostatically pressed and slip cast for use as an alloying agent in slip casting processes. Furthermore, green or biscuit machined surfaces may also be metalized for brazing purposes.

High Strength

Alumina ceramics possess high strengths of strength, hardness and corrosion resistance – qualities which allow them to withstand pressure conditions when used in applications where strength and abrasion resistance may be crucial.

Metalized ceramic parts made of alumina can also be formed into high-pressure components for welding nozzles, thermal insulators, X-ray and electron tubes, ergonomic body armour tiles or monolithic tiles for ergonomic body armour applications.

These materials can withstand chemical attacks such as acid and alkali corrosion, making them suitable for food processing, pharmaceutical production and everyday uses.

High Hardness

Alumina (Al2O3) is one of the hardest engineered ceramics. Higher purity grades offer impressive resistance to abrasion and wear; superior electrical properties with outstanding thermal conductivity; inertness, and good resistance against chemicals that could corrode it.

Chromium oxide improves hardness; silicon dioxide enhances conductivity; manganese oxide helps improve color and hardness; zirconium oxide provides increased corrosion resistance for alumina ceramics, while other additives increase strength, machinability and crack deflection capabilities of these materials.

Excellent Biocompatibility

Due to their chemical resistance and inertness, alumina ceramics have long been utilized as bioceramics. With superior bone tissue compatibility and the potential for direct connections with new bone growth, alumina ceramics offer numerous applications in biomedicine.

Ceramic materials are increasingly being utilized in artificial bones, tooth implants and joints due to their resistance to abrasion, radiation and temperature effects – they can even be made into tubing sheets rods and discs for various applications.

Dental alumina ceramics made of aluminum oxide have shown outstanding biocompatibility during clinical trials, as there is no way for raw metallic aluminum to escape and enter the body from these dental porcelains.